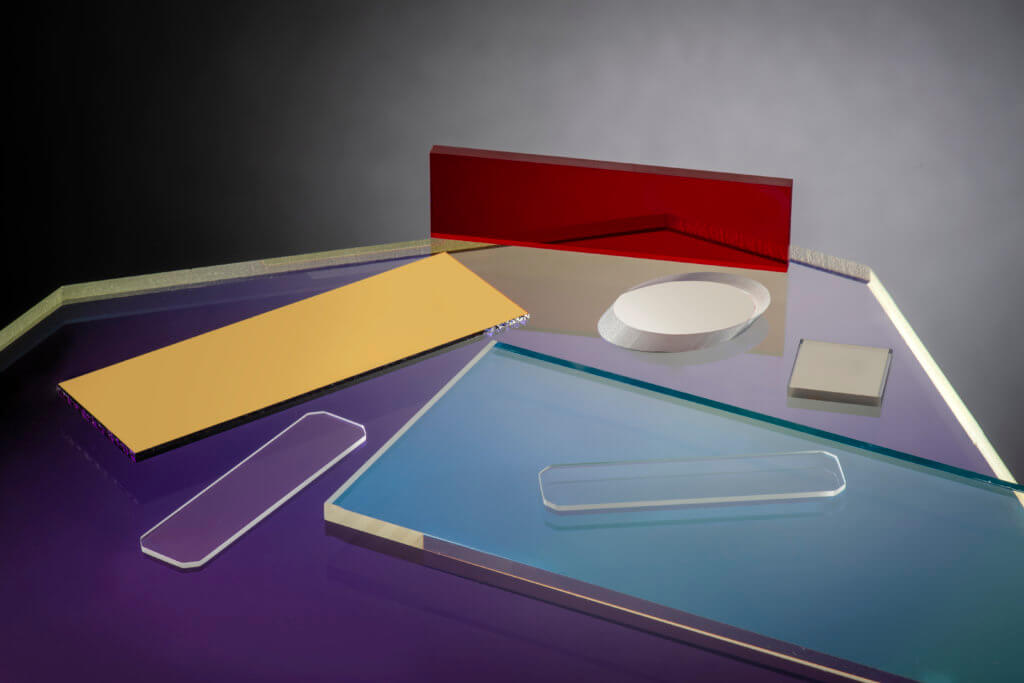

With over six decades of experience engineering and manufacturing solutions for custom glass fabrication, Specialty Glass Products is a global leader in the design and manufacturing of glass products for specific applications and advanced technology-driven industries.

Specialty Glass Products Precisely Fabricates Glass Products for:

Specific Applications:

- Medical Lasers: High-purity fused quartz and specialty optical glass are crucial for components like laser cavities, windows, and lenses, due to their excellent transmission properties and resistance to thermal shock, ensuring precise and reliable medical procedures.

- Fiber Optics: Precision drawn glass and quartz fibers, often made from high-purity silica, are essential for transmitting light signals over long distances with minimal loss, forming the backbone of modern communication networks.

- Cytology: Borosilicate and specialty glass slides, coverslips, and microfluidic devices are utilized for their optical clarity, chemical inertness, and precise dimensions, enabling accurate microscopic examination and analysis of cells.

- Spectrophotometry: UV-grade fused quartz and optical glasses are employed in cuvettes, windows, and prisms due to their specific light transmission characteristics across various wavelengths, allowing for accurate absorption and transmission measurements.

- Semiconductor Assemblies: High-purity fused quartz and specialty borosilicate glass are used for components like furnace tubes, boat supports, and wafers due to their thermal stability, chemical resistance, and electrical insulation properties, critical for semiconductor processing.

Photo & X-ray Lithography: Ultra-flat, low-thermal-expansion glass and fused quartz substrates are vital for photomasks and reticles, providing the dimensional stability and optical clarity necessary for precise pattern transfer in microfabrication.

Photo & X-ray Lithography: Ultra-flat, low-thermal-expansion glass and fused quartz substrates are vital for photomasks and reticles, providing the dimensional stability and optical clarity necessary for precise pattern transfer in microfabrication.- Micro-Orifices: Precision-drilled glass and quartz components are engineered for their accurate and consistent hole sizes, often used in applications requiring precise fluidic control, such as in medical diagnostics or inkjet printing.

- Beam Splitters: Optically flat and precisely coated glass or fused quartz substrates are used to divide light beams into two or more paths, critical in various optical systems for measurement, imaging, and laser applications.

- Substrates: Dimensionally stable and highly polished glass and quartz sheets provide the foundational support for thin-film coatings, electronic circuits, and display technologies due to their flatness, smoothness, and customizable properties.

- Wafers: Highly polished and ultra-flat disks of glass or fused quartz serve as base materials for semiconductor devices, MEMS, and other microelectronic components, providing a stable platform for subsequent processing and deposition.

Advanced Technology-Driven Industries:

- Biomedical Equipment: Precision-fabricated borosilicate, fused quartz, and specialty optical glass are used in diagnostic instruments, laboratory equipment, and medical devices due to their biocompatibility, optical clarity, and chemical resistance.

- Communications: High-purity silica glass is fundamental to fiber optic cables and components like lenses and ferrules, enabling high-speed data transmission and reliable network infrastructure globally.

- Laser Manufacturing: Specialty optical glass, fused silica, and sapphire are employed in laser optics, including lenses, windows, and gain media, selected for their specific refractive indices, transmission, and damage threshold properties.

- Aerospace & Avionics: Lightweight, high-strength, and thermally stable specialty glasses and fused quartz are critical for cockpit displays, optical sensors, and protective windows, ensuring reliability in extreme environmental conditions.

- Semiconductor Technology: Ultra-pure fused quartz and specialized borosilicate glasses are essential for various process tools, masks, and components within semiconductor fabrication, due to their thermal shock resistance, chemical inertness, and electrical insulation.

- Fiber Optics: Precision drawn glass and quartz, often made from high-purity silica, are essential for modern communication networks.

- Electronics: Custom-fabricated glass and quartz components are used in displays, sensors, and protective covers due to their electrical insulation properties, optical transparency, and ability to be precisely shaped for various electronic devices.

- Laboratory Measurement Instruments: High-quality fused quartz, borosilicate, and specialty optical glasses are essential for components like cuvettes, flow cells, lenses, and prisms in instruments such as spectrophotometers and chromatographs, where their superior optical clarity, chemical resistance, and precise dimensional stability ensure accurate and reproducible analytical results.

- High Temperature Furnaces: Fused quartz and high-purity silica are utilized for viewing windows, sight glasses, and thermal barriers in high-temperature furnaces and reactors due to their exceptional thermal shock resistance, extremely low thermal expansion, and ability to maintain optical clarity at sustained high operating temperatures.

To learn more about how SGP Inc. can help you with your application please submit an inquiry, or contact us directly.