CNC Centerless Grinding & Polishing

Leveraging our centerless grinding and polishing capabilities, Specialty Glass Products produces premier quality precision tubing and rod. We obtain very tight tolerances, as close as ±.0001”, on outer diameter and inner diameter while creating excellent surface finishes. From the very first grinding step through to the final polish, we take a quality-oriented approach to deliver products of the highest caliber.

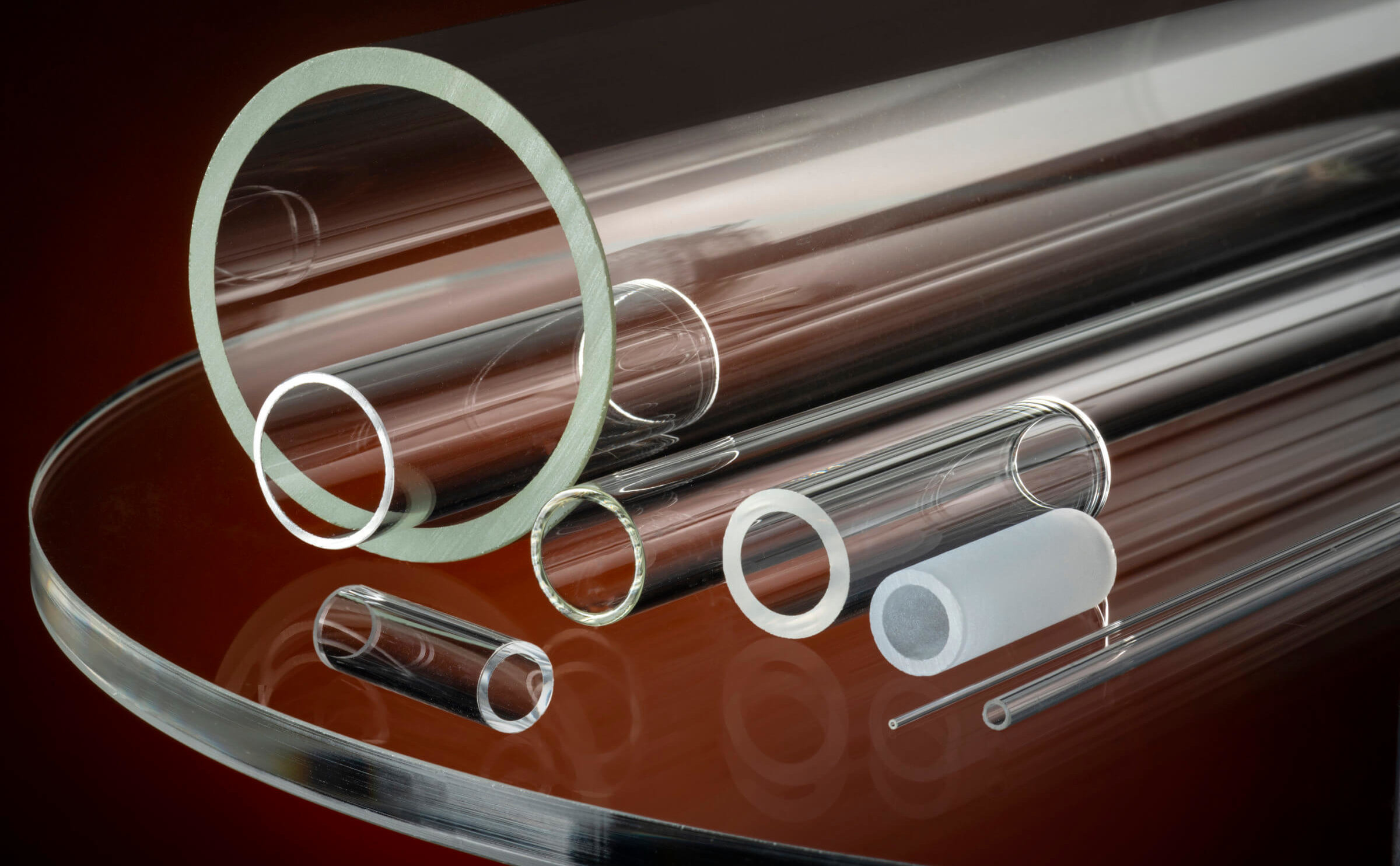

With our CNC centerless grinders outfitted with diamond disks, we produce glass rods and tubes that exhibit excellent roundness, straightness, and surface finish. We process rod and tube from .003” to 2.5” in diameter and tubing with ID anywhere in the .060” to 2.0” range. Length can be up to 25.0”, and centerless grinding of complex shapes with tapers, multiple diameters, and rectangle and square profiles is easily accomplished. Using a series of rough to fine grits, we create smooth pre-polish surfaces and then fire polish or mechanically polish to meet the required transmission specification. Ends can be ground or polished to an optical finish. Along with various types and grades of fused quartz and fused silica, we offer ground and polished SCHOTT Duran and Corning® Pyrex borosilicate glass rod and tube as well as soda-lime glass products, synthetic sapphire, and high transmission optical glass.

As an industry-leading glass manufacturing company, we take quality very seriously. We have implemented a compliant ISO 9001:2015 manufacturing environment, and our processes and products conform to industry standards. Our high-quality tubing and rod products are used in a wide range of applications in technology-driven industries. Contact us directly for more detailed information about our centerless grinding and polishing processes for glass and quartz tubing and rod. We welcome the opportunity to provide a quote.