Home » Materials » Borosilicate » SCHOTT Borofloat® 33 Glass

Glass Type: Borosilicate

Description

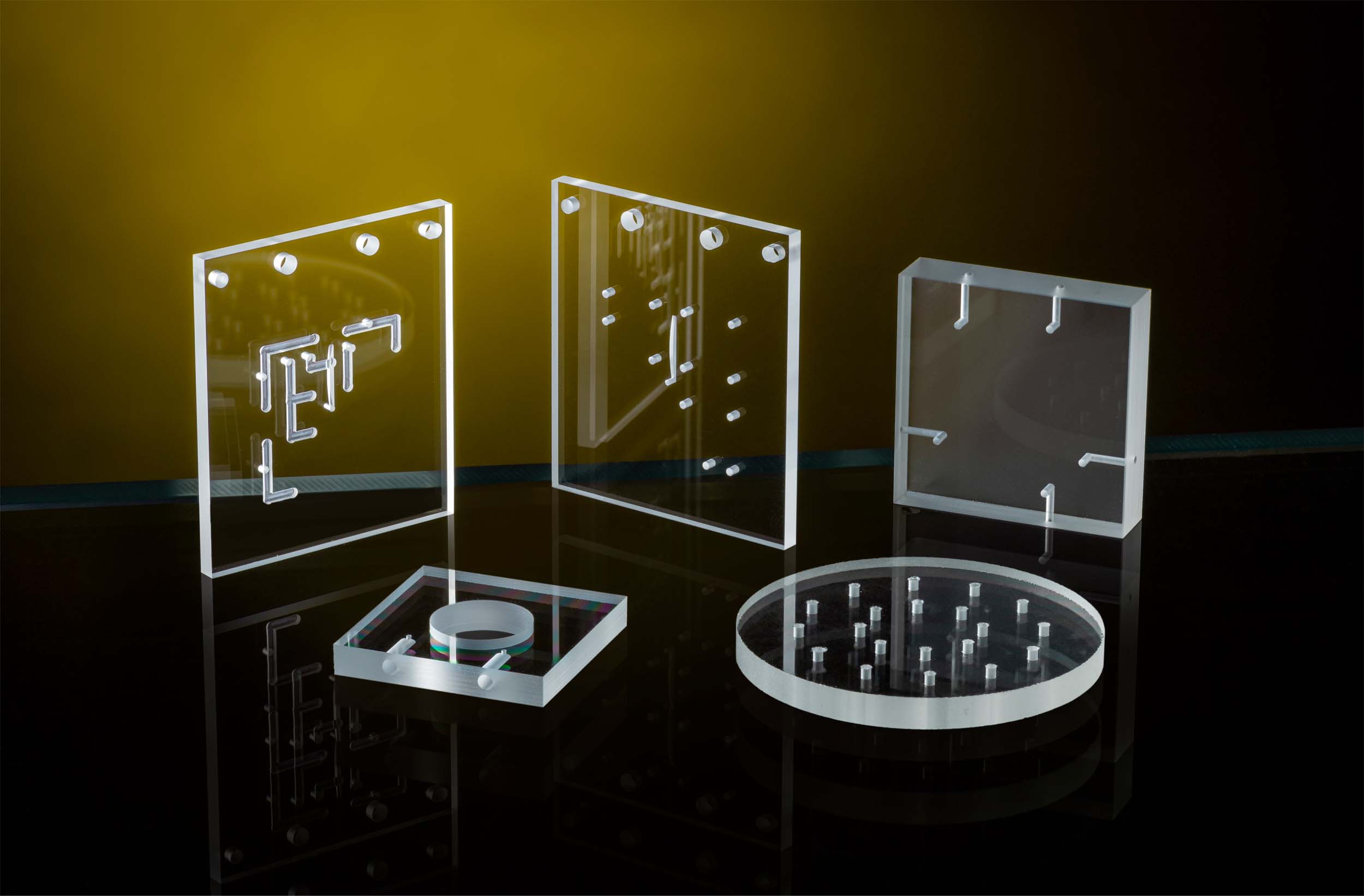

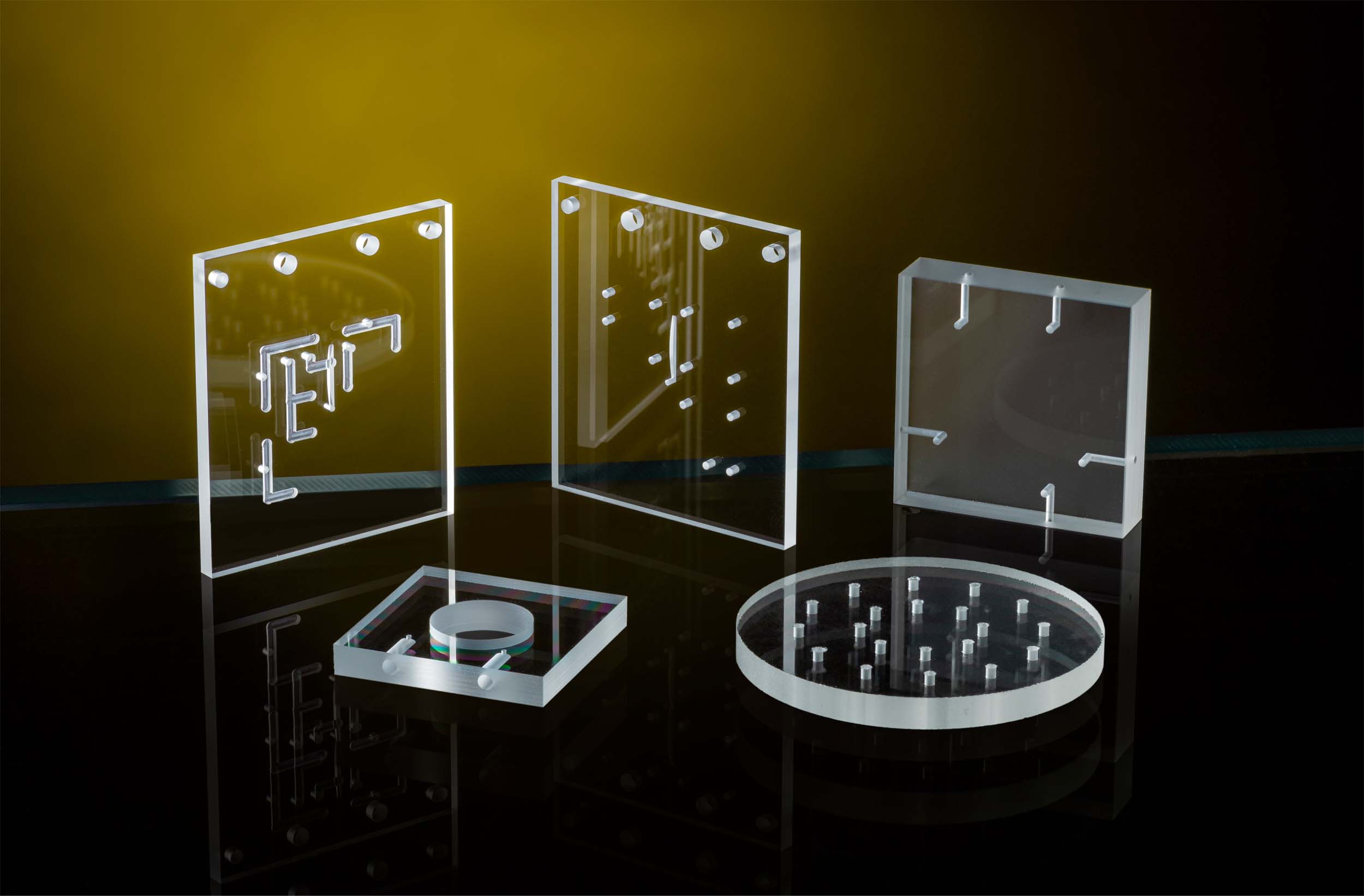

SCHOTT Borofloat® glass is a highly chemical resistant borosilicate glass with low thermal expansion that is produced using a float process. Other key properties of Borofloat® glass include an average 80/50 scratch/dig surface quality, high thermal resistance and excellent transmission. Borofloat® can be used as a substitute for Corning® Pyrex® in most cases. The materials differ slightly in chemical composition. SGP can CNC mill, drill, cut, lap, and polish Borofloat® to any dimension, shape or surface finish.

| Thermal Properties | | | Mechanical Properties |

|---|

| Thermal Coefficient of

Expansion | (0/300°C): 32.5 X 10 -7/°C | Density | 2.23 g/cm3 (at 25 °C/77°F) |

| Annealing Point | 560°C / 1040° F | Knoop Hardness | HK0.1/20:480 |

| Softening Point | 815°C / 1508°F | Young’s Modulus | N/A |

| Strain Point | N/A | Poisson’s Ratio | 0.20 |

| Chemical Properties | | | Electrical Properties |

|---|

| Hydrolytic Resistance | class 1 | Dielectric Constant | E=4.6 @/MHz &25°C |

| Acid Resistance | class 1 | Resistivity | 8.0 X 250°C; 6.5 @ 350°C |

| Alkali Resistance | class 2 | Dielectric Strength | 16 KV/mm @50 Hz & 25°C |

| Optical Properties | |

|---|

| Refractive Index | 1.472 |

When is Schott Borofloat 33 Glass My Best Material Choice?

Schott Borofloat 33 Glass is a high-quality borosilicate glass known for its outstanding thermal resistance, exceptional mechanical strength, and superior optical properties. Manufactured using a micro-float process, Borofloat 33 offers an impressive combination of low thermal expansion, high chemical resistance, and excellent transparency, making it an ideal material for demanding industrial and scientific applications.

Its advanced composition and float-glass production process ensure high surface quality, outstanding flatness, and uniformity, making it a preferred choice for high-precision optical and technical applications. Schott Borofloat 33 Glass is available in a variety of thicknesses ranging from 0.7 mm to 25.4 mm, catering to diverse industrial needs while maintaining consistent performance and durability.

With an exceptional balance of thermal, mechanical, and optical properties, Borofloat 33 Glass is widely used across industries requiring high-performance materials with reliability under extreme conditions.

Characteristics of Schott Borofloat 33 Glass:

- Exceptional Thermal Resistance: Its low thermal expansion coefficient ensures excellent thermal shock resistance, making it ideal for high-temperature applications.

- Superior Optical Transparency: High transmittance in the visible and infrared spectrum allows for excellent optical clarity in precision applications.

- High Mechanical Strength: Superior mechanical properties, including excellent impact and scratch resistance, provide durability in demanding environments.

- Outstanding Chemical Stability: Exceptional resistance to acids, alkalis, and other aggressive chemicals, ensuring long-term reliability in harsh conditions.

- High Homogeneity: Ensures minimal optical distortion, providing consistent performance in optical and scientific applications.

- Excellent Surface Quality: Manufactured through the float-glass process, Borofloat 33 features a smooth, high-quality surface that enhances its performance in coatings and optical applications.

- Wide Temperature Range: Capable of withstanding extreme temperatures up to 450°C continuously and short-term exposure up to 550°C.

- Good Electrical Insulation: High electrical resistivity makes it suitable for applications requiring electrical insulation properties.

- Versatile Processing Capabilities: Easily cut, drilled, and processed to meet specific design requirements while maintaining its superior characteristics.

- Thermally Temperable: Borofloat 33 glass is thermally temperable, providing enhanced mechanical strength and thermal shock resistance.

Top Five Industries and Applications of Schott Borofloat D33 Glass:

- Optics and Photonics:

- Optical lenses, mirrors, and windows for high-performance imaging and laser applications.

- Substrates for optical coatings, ensuring precision and durability in optical components.

- Medical and Biotechnology:

- Substrates for medical diagnostic devices and analytical instruments requiring high chemical resistance and optical clarity.

- Laboratory glassware and microfluidic devices benefiting from Borofloat 33’s durability and stability.

- Aerospace and Defense:

- Protective glass covers for sensitive optical and electronic instruments.

- Lightweight yet durable windows for aircraft and space applications.

- Heat-resistant glass for infrared sensing and targeting systems.

- Industrial and Engineering Applications:

- High-temperature sight glasses/ viewports for industrial processing equipment.

- Protective barriers and shields for high-precision laser and welding systems.

- Durable substrates for semiconductor and electronics manufacturing.

- Research and Laboratory Equipment:

- Transparent furnace windows/viewports for high-temperature experimental setups.

- Optical components for spectroscopy and microscopy applications.

- Chemical-resistant glassware for advanced research and chemical processing.

Schott Borofloat 33 Glass is a versatile and high-performance material that meets the stringent demands of modern industries. Its exceptional thermal stability, optical clarity, and mechanical strength make it an essential component in cutting-edge technologies across multiple high-tech sectors.

SGP is a trusted leader in precision glass machining and fabrication, backed by years of expertise working with Schott Borofloat® 33 glass across a wide range of industries and applications.

Whether you’re seeking more information about this high-performance material, or need a quote for your specific project, our team is here to help. Contact us today with your questions or requirements—we’re ready to support your application from concept to completion.