At Specialty Glass Products, we utilize our chemical strengthening and heat tempering capabilities to harden soda-lime glass and borosilicate glass to make it more resistant to scratching, cracking, or breaking. We use standards-compliant testing and quality assurance to ensure our products are of the highest caliber.

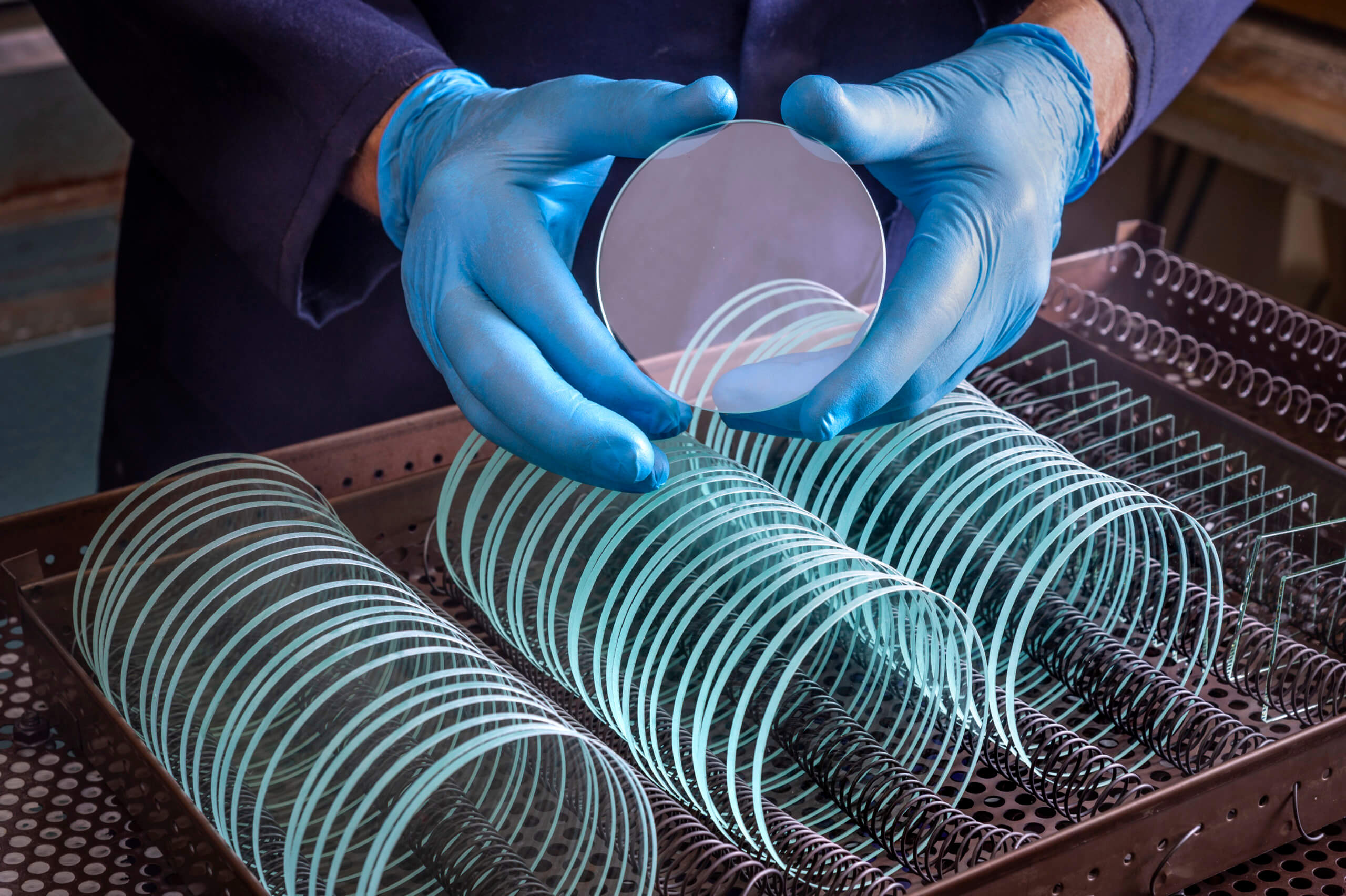

For chemical strengthening, our ion exchange process involves submerging glass in a potassium salt bath for eight to 16 hours. We vary the soak time, chemical composition of the bath, and process temperatures based on the end-use application requirements. Our computer-controlled and monitored chemical strengthening process creates distortion-free, high-performance glass with a toughened surface that exhibits impressive impact strength and scratch resistance. We chemically strengthen glass measuring up to 36” long x 72” wide and from .004” to 3.0” in thickness.

Our heat tempering process, in which the glass is heated and rapidly cooled, increases the strength and heat resistance while making the glass much less susceptible to breaking. If the glass does break, it disintegrates into small, harmless pieces. We also offer heat strengthening, which is similar to tempering, but the heated glass is cooled at a much slower pace. Heat-strengthened glass is stronger, exhibits excellent thermal stability, and offers better light transmission than tempered glass. We can heat strengthen glass from .04” to .24” thick and temper glass from .25” to 2.5” thick.

Quantity pricing can be quoted from engineering prototypes through production volumes.